In the UK building industry, we talk constantly about fire barriers, fire stopping, and compartmentation. But too often, the conversation stops at the barrier itself - the batt, the wrap, or the sealant. The truth is the most high-performance fire barrier in the world can be completely ineffective if it isn't anchored to a suitable substrate.

You're installing life-saving protection into a void. You’ve sealed the penetration; you’ve installed the cavity barrier. Job done, right? Not if the wall or floor you’re fixing it to fails faster than the barrier itself. This concept is fundamental, yet it remains one of the most common oversights on site.

Table of Contents

- What is the most critical factor for a fire barrier's performance, and how do I know if my substrate is suitable under UK building regulations?

- The Four Cornerstones of Substrate Suitability

- The components surrounding the barrier must remain stable

- Cavity Barriers, unless designed to do so, should not abut Thermal Insulation

- The substrate must be fire resisting

- Always check the product data sheet and certification

- Summary: The weakest link

What is the most critical factor for a fire barrier's performance, and how do I know if my substrate is suitable under UK building regulations?

The key factor isn't the fire barrier's rating alone; it's the stability and fire resistance of the entire system, and that starts with the supporting element - the substrate.

UK fire safety legislation requires that measures must be taken to inhibit the unseen spread of fire and smoke within concealed spaces [1]. For a fire barrier or fire stop to meet its required Integrity (E) and Insulation (I) rating, the surrounding structure must maintain its stability for at least the same duration [4].

If you fix a 120-minute fire collar into a wall that only lasts 30 minutes, your overall system performance is still only 30 minutes. The system is only as strong as its weakest link.

The Four Cornerstones of Substrate Suitability

Ensuring compliance and, more importantly, life safety, comes down to four fundamental checks concerning your chosen substrate, all governed by the principle of system integrity:

1. The components surrounding the barrier must remain stable

For any cavity barrier or fire stopping system to be effective, it is non-negotiable that the components surrounding it - the walls, floors, or sheathing boards - must remain stable for the same period of time as required from the fire barrier. Approved Document B (ADB) [2] guidance on compartmentation, emphasises that every joint or opening must be sealed or fire-stopped to maintain the element's integrity. If the supporting element becomes unstable and deforms or collapses, the seal is broken.

2. Cavity Barriers, unless designed to do so, should not abut Thermal Insulation

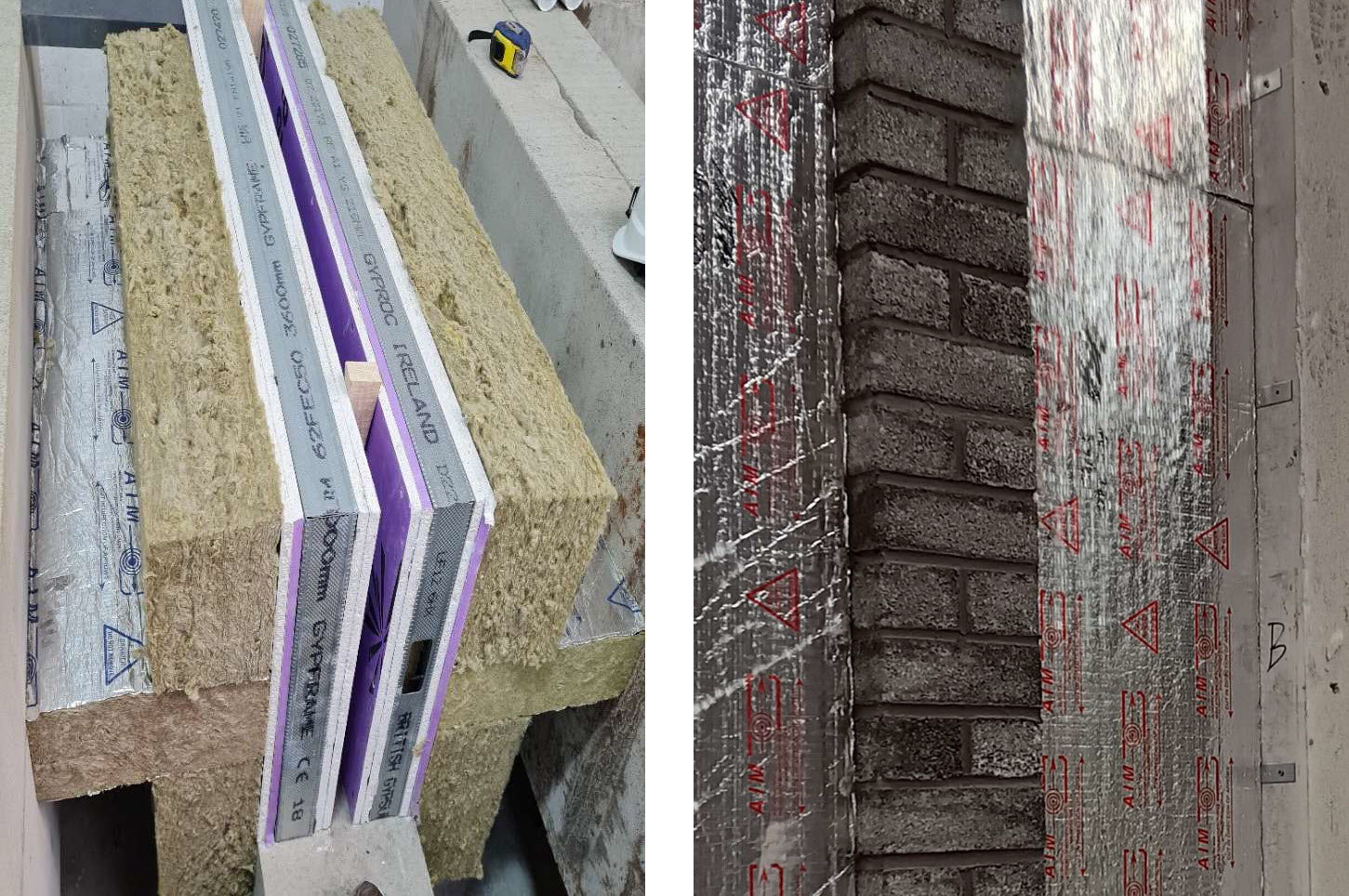

The general rule is cavity barriers should never abut thermal insulation, especially highly combustible materials.

- Combustible Insulation (e.g., Polystyrene/EPS): If you install a barrier directly against a material like polystyrene, the fire will burn around the cavity barrier in a matter of seconds. The expanding fire barrier will be immediately bypassed by the rapidly burning or melting substrate.

- Non-Combustible Insulation: Even if the insulation in the cavity is a form of stone wool, it is unlikely to be the correct density and grade to be used as a cavity barrier itself. Fire barriers are specifically manufactured, tested, and certified for their sealing properties and must be tightly fixed to a rigid, fire-resisting construction, not a compressible or unstable insulating material [2, Section 9].

Note there are products on the market that are able to do this but it’s always recommended to check with the manufacturer to be completely sure.

3. The substrate must be fire resisting

The rigidity and composition of the material you fix to is key.

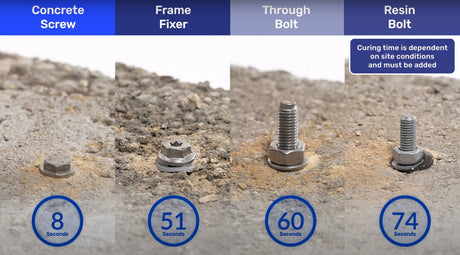

- Concrete & Masonry: Concrete or blockwork is by far the best substrate due to its inherent non-combustibility [3] and structural stability under fire. When fixed to these materials, a fire barrier has a robust, reliable anchor.

-

Sheathing Boards: Sheathing boards are very common in modern and timber frame constructions. Here, due diligence is vital.

- Cement-Based Boards are generally robust, but their stability in a fire situation should still be confirmed with the manufacturer.

-

OSB (Oriented Strand Board) or Plywood are common in timber frame constructions. These are combustible materials. If they form part of the separating element, the stability of the sheet as a whole in a fire situation must be explicitly confirmed with the board manufacturer, in conjunction with the fire barrier manufacturer.

4. Always check the product data sheet and certification

This is the ultimate rule for compliance and safety. Always check the product data sheet and the associated test report.

Manufacturers, like our trusted partners, AIM spend considerable time and expense testing their products, and these test reports will specify the exact substrates the product has been successfully tested against. The field of application (or scope of certification) is strictly defined and details the construction, thickness, and density of the tested substrate.

If the documentation doesn’t specifically say the product can be used against a particular board, you must check with the manufacturer directly. The industry best practice is that most trusted manufacturers will only show pictures and details of their products in the applications they are suitable for. If your application doesn't match the test data, the system is non-compliant, and its performance is compromised.

Summary: The weakest link

The performance of any fire barrier system is intrinsically tied to the stability and fire-resisting properties of the substrate it is fixed against. Compliance is achieved not just by installing certified fire-stopping products, but by ensuring the entire construction system - including the wall or floor - is tested and rated to the same, or a greater, level of fire resistance. Always verify substrate compatibility against the fire barrier product's official test data and certification [4].

Kevin Blake, of AIM closes out this topic with some sage like advice,

“The rules are simple: For any cavity barrier to be effective, cavity barriers should not abut unapproved thermal insulation. The substrate must be fire resisting. And most of all - Always check the product’s data for suitability.”

References

All fire stopping and cavity barrier installations must be compliant with the following:

- The Building Regulations 2010, Requirement B3 (Internal Fire Spread - Structure) https://www.legislation.gov.uk/uksi/2010/2214/contents

- Approved Document B (Fire Safety), Volumes 1 & 2 (Guidance on compliance, including Section 9 for cavity barriers) https://www.gov.uk/government/publications/fire-safety-approved-document-b

- BS EN 13501-1 (Fire classification of construction products) https://knowledge.bsigroup.com/products/fire-classification-of-construction-products-and-building-elements-classification-using-data-from-reaction-to-fire-tests

- BS EN 1366 Series (Fire resistance tests for service installations) https://knowledge.bsigroup.com/products/fire-resistance-tests-for-service-installations-penetration-seals-4