fischer FAZ II PLUS 8/30 ZP M8 x 58 zinc through bolt [564575]

| GTIN (EAN Code): 4048962462005 |

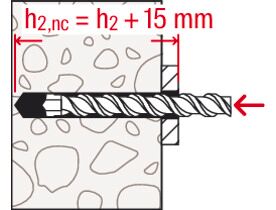

| Drill diameter: 8mm |

| Min. drill hole depth for through fixings: 85mm |

| Anchor length: 95mm |

| Max. usable length hef,stand./hef,min.: 30 / 40mm |

| Width across nut: 13mm |

| Thread: M8 x 58mm |

| Seismic-Approval: C1 |

Unit of Measure Name:

50

Internal Reference:

564575

Description

Fischer FAZ II Plus is a high-tensile strength steel anchor for non-cracked/cracked concrete. It uses a tried-and-tested expansion clip to safely introduce loads into the concrete, enabling an immediately loadable high load-bearing capacity. It is ideal for anchoring railings, cable trays, and consoles.

Product Features

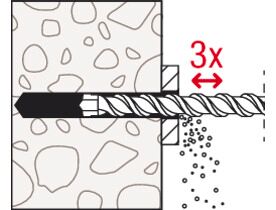

- No need for drill hole cleaning (M8-M24): Quick and easier assembly.

- Numerous approval certificates for different substrate materials (concrete C12/15-C80/90, steel fibre concrete, solid sand-lime brick): Increase the number of applications and fields of use.

- With the new assessment (ETA), the tensile strengths increase decisively: Fewer fixing points and anchors are required.

- ETA evaluation, together with other test reports (RWS, ZTV, ETK): High loads in case of fire.

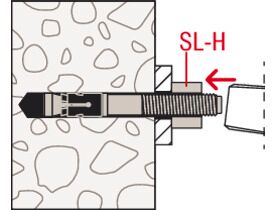

- Variable anchorage depths: Allows a millimetre-accurate adjustment to the loads.

- The FAZ II Plus allows the absorption of high seismic loads of performance category C1 with and without the use of the filling disc FFD at installation: Flexible.

Applications

Steel constructions

Guard rails

Consoles

Ladders

Cable trays

Machines

Staircases

Façades

Timber constructions

Building Materials

Approved for:

Concrete C20/25 to C50/60, cracked and non-cracked

Also suitable for:

- Concrete C12/15 (classification available)

- Concrete C80/95 (classification available)

- Steel fibre concrete (classification available)

- Solid sand-lime brick (classification available)

You can find detailed information on building materials in the registration document.

Certification

ETA-19/0520

DoP 0334

ESR-2948

Functionality

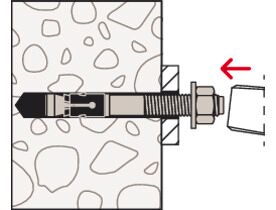

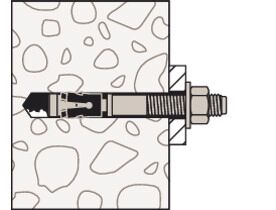

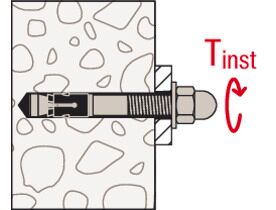

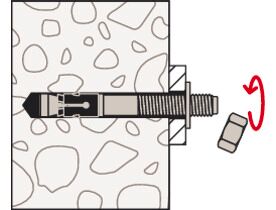

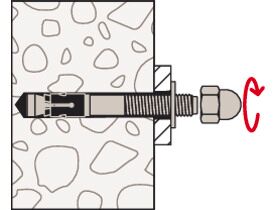

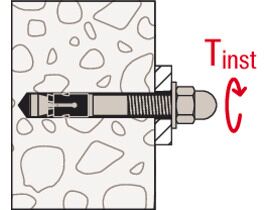

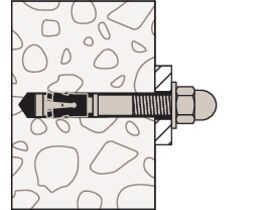

The FAZ II PLUS is suitable for pre-positioned and push-through installation, and is also ideal for stand-off installation thanks to the long thread.

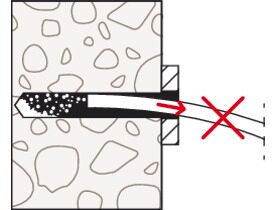

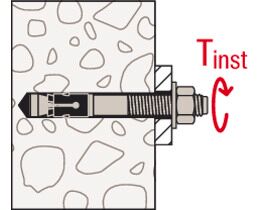

When applying the torque, the cone bolt is pulled into the expansion sleeve and expand it against the drill hole wall.

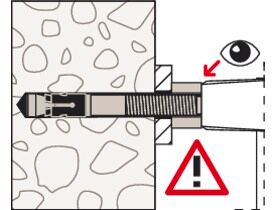

The anchor is set in line with the approval once the preset installation torque is achieved.

- In the case of series installation, we recommend using the FABS or FA-ST II anchor bolt setting tools.

| Document Name | Download |

| Declaration of Performance | |

| ETA Approval | |

| ICC Approval | |

| Load Table | |

| Load Table (Dynamic) |

![fischer FAZ II PLUS 8/30 ZP M8 x 58 zinc through bolt [564575]](/web/image/product.product/10693/image_1024/%5B564575%5D%20fischer%20FAZ%20II%20PLUS%208-30%20ZP%20M8%20x%2058%20zinc%20through%20bolt%C2%A0%5B564575%5D?unique=db15c13)

![fischer FAZ II PLUS 8/30 ZP M8 x 58 zinc through bolt [564575]](/web/image/product.image/2598/image_1024/fischer%20FAZ%20II%20PLUS%208-30%20ZP%20M8%20x%2058%20zinc%20through%20bolt%C2%A0%5B564575%5D?unique=fa77243)

![fischer FAZ II PLUS 8/30 ZP M8 x 58 zinc through bolt [564575] 1](/web/image/product.image/2599/image_1024/fischer%20FAZ%20II%20PLUS%208-30%20ZP%20M8%20x%2058%20zinc%20through%20bolt%C2%A0%5B564575%5D%201?unique=fa77243)

![fischer FAZ II PLUS 8/30 ZP M8 x 58 zinc through bolt [564575] 2](/web/image/product.image/2600/image_1024/fischer%20FAZ%20II%20PLUS%208-30%20ZP%20M8%20x%2058%20zinc%20through%20bolt%C2%A0%5B564575%5D%202?unique=fa77243)

![fischer FAZ II PLUS 8/30 ZP M8 x 58 zinc through bolt [564575] 3](/web/image/product.image/2601/image_1024/fischer%20FAZ%20II%20PLUS%208-30%20ZP%20M8%20x%2058%20zinc%20through%20bolt%C2%A0%5B564575%5D%203?unique=fa77243)

![fischer FAZ II PLUS 8/30 ZP M8 x 58 zinc through bolt [564575] 4](/web/image/product.image/2602/image_1024/fischer%20FAZ%20II%20PLUS%208-30%20ZP%20M8%20x%2058%20zinc%20through%20bolt%C2%A0%5B564575%5D%204?unique=fa77243)

![fischer FAZ II PLUS 8/30 ZP M8 x 58 zinc through bolt [564575]](/web/image/product.product/10693/image_128/%5B564575%5D%20fischer%20FAZ%20II%20PLUS%208-30%20ZP%20M8%20x%2058%20zinc%20through%20bolt%C2%A0%5B564575%5D?unique=db15c13)

![fischer FAZ II PLUS 8/30 ZP M8 x 58 zinc through bolt [564575]](/web/image/product.image/2598/image_128/fischer%20FAZ%20II%20PLUS%208-30%20ZP%20M8%20x%2058%20zinc%20through%20bolt%C2%A0%5B564575%5D?unique=fa77243)

![fischer FAZ II PLUS 8/30 ZP M8 x 58 zinc through bolt [564575] 1](/web/image/product.image/2599/image_128/fischer%20FAZ%20II%20PLUS%208-30%20ZP%20M8%20x%2058%20zinc%20through%20bolt%C2%A0%5B564575%5D%201?unique=fa77243)

![fischer FAZ II PLUS 8/30 ZP M8 x 58 zinc through bolt [564575] 2](/web/image/product.image/2600/image_128/fischer%20FAZ%20II%20PLUS%208-30%20ZP%20M8%20x%2058%20zinc%20through%20bolt%C2%A0%5B564575%5D%202?unique=fa77243)

![fischer FAZ II PLUS 8/30 ZP M8 x 58 zinc through bolt [564575] 3](/web/image/product.image/2601/image_128/fischer%20FAZ%20II%20PLUS%208-30%20ZP%20M8%20x%2058%20zinc%20through%20bolt%C2%A0%5B564575%5D%203?unique=fa77243)

![fischer FAZ II PLUS 8/30 ZP M8 x 58 zinc through bolt [564575] 4](/web/image/product.image/2602/image_128/fischer%20FAZ%20II%20PLUS%208-30%20ZP%20M8%20x%2058%20zinc%20through%20bolt%C2%A0%5B564575%5D%204?unique=fa77243)

![fischer FAZ II PLUS 8/30 ZP M8 x 58 zinc through bolt [564575] video](/web/image/product.image/2603/image_128/fischer%20FAZ%20II%20PLUS%208-30%20ZP%20M8%20x%2058%20zinc%20through%20bolt%C2%A0%5B564575%5D%20video?unique=fa77243)